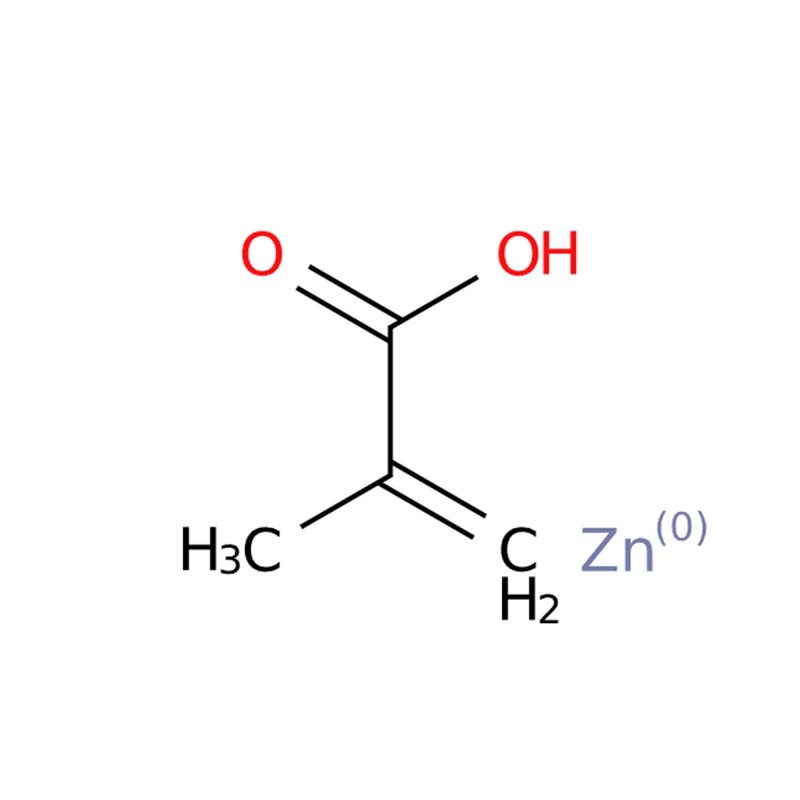

Zinc methacrylate

Broad Industrial Usage: Commonly applied in rubber production, automotive sealants, cable sheath adhesives, and a variety of other industries.

Superior Heat Resistance: Increases the durability of products, ensuring reliable performance even under high temperatures.

Robust Oil and Corrosion Resistance: Extends the lifespan and reliability of materials by offering strong protection against oil and corrosion.

Improved Mechanical Strength: Significantly enhances the performance of rubber products, making them more resilient.

This essential organozinc compound is widely used across multiple industries, including rubber manufacturing, automotive sealants, cable sheath adhesives, and related applications.

It delivers excellent heat, oil, and corrosion resistance, along with enhanced mechanical performance, contributing to the durability and functionality of rubber products.

To ensure safety for personnel and environmental protection, strict adherence to handling and storage protocols is required during its use.

Parameters

Melting point | 229-232 °C(lit.) |

density | 1,4 g/cm3 |

vapor pressure | 0Pa at 20℃ |

storage temp. | Inert atmosphere,Room Temperature |

form | |

Specific Gravity | 1.48 |

Water Solubility | 100mg/L at 20℃ |

Hydrolytic Sensitivity | 4: no reaction with water under neutral conditions |

InChIKey | PIMBTRGLTHJJRV-UHFFFAOYSA-L |

LogP | 0.3 at 25℃ |

CAS DataBase Reference | 13189-00-9(CAS DataBase Reference) |

EPA Substance Registry System | Zinc dimethacrylate (13189-00-9) |

Safety Information

Hazard Codes | Xi |

Risk Statements | 36/37/38-43 |

Safety Statements | 26-36 |

WGK Germany | 3 |

TSCA | Yes |