Upgrading the Paraffin Industry: The Transformation from Basic Raw Material to High Value-Added Material

Within the global chemical industry chain, a traditional yet important product—paraffin—is quietly undergoing a profound transformation from being "scale-driven" to "value-led."

Global Market Structure and Growth Pressures

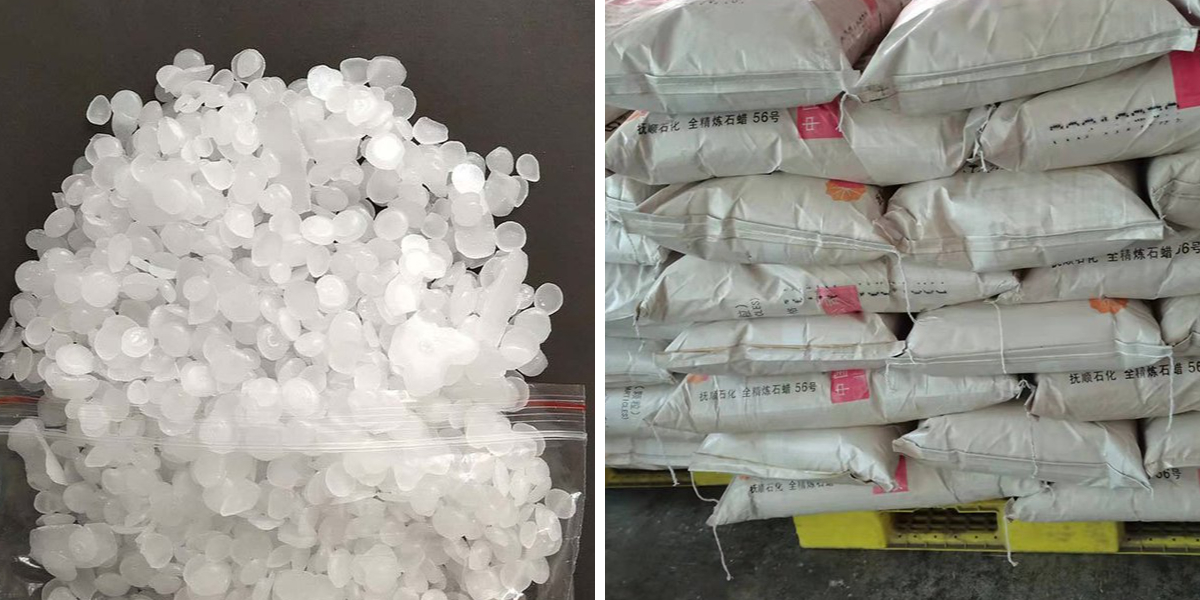

Paraffin is a solid hydrocarbon mixture refined from petroleum. Due to its stable chemical properties and relatively low cost, it is widely used in various fields such as candle making, packaging coatings, rubber protection, cosmetics, and electrical insulation.

For a long time, leveraging abundant petroleum resources and a complete refining and chemical industry chain, China has held a central position in the global paraffin supply, being the world's largest producer and exporter of paraffin.

However, the industry is facing structural challenges. The growth in global paraffin demand is being squeezed by both substitution from synthetic waxes and the rise of eco-friendly packaging materials. Particularly in mature markets like Europe and America, stricter environmental policies and changing consumer preferences are slowing the demand growth for traditional paraffin candles and packaging materials.

Industry data indicates that the profit margins for specialty and high-end waxes are far higher than those for conventional products. Yet, their share in China's total paraffin output remains significantly lower than the levels in developed markets like Japan and Western Europe. Product homogeneity and low added value are the main bottlenecks constraining the industry's development.

Breaking Through Bottlenecks: Transitioning Towards "High-End and Specialization"

In response to these challenges, the entire industry has embarked on a transformation path centered on "reducing oil output while increasing specialty products" and moving towards the "high-end." The core of this strategy is to adjust the product mix, reducing the proportion of bulk commodity products, and focusing efforts on developing high value-added specialty wax products with specific properties that meet the needs of niche markets.

Technological upgrading is the cornerstone of this transformation. Traditional paraffin production facilities are undergoing technical modifications to enhance production flexibility and product precision. For example, technological routes like "integrated oil and wax production" are gaining attention. This approach allows for optimized utilization of raw materials, enabling flexible production of paraffin with different melting points, microcrystalline wax, and specialty lubricant components within the same set of equipment, greatly diversifying the product portfolio.

The R&D focus is now concentrated on a series of high-performance specialty waxes:

Rubber Protective Wax: Used in industries like tire manufacturing to prevent rubber aging.

Phase Change Energy Storage Wax: Applied in areas like building energy efficiency and industrial waste heat recovery, representing a green energy material.

Precision Casting Wax: Serves the mold manufacturing needs of high-end manufacturing industries such as aerospace.

Food-Grade and Cosmetics-Grade Specialty Wax: Requires extremely high standards for purity, safety, and sensory indicators.

The commonality of these products lies in the fact that they are no longer general-purpose commodities. Instead, they are functional materials "tailor-made" for specific physical properties (such as melting point, hardness, adhesion), chemical stability, or safety standards.