Advanced Resins for Composites CAS29690-82-2

Resins are high-molecular-weight polymers synthesized chemically, offering exceptional moldability, adhesion, chemical resistance, and electrical insulation. As critical base materials for composites, coatings, adhesives, and electronic encapsulation, the performance of resins directly determines the quality of final products. We provide a comprehensive range, including Epoxy, Polyurethane, Unsaturated Polyester, and Acrylic resins, catering to diverse industrial needs.

Part 1: Detailed Specifications & Technical Data

Table 1: Core Parameter Comparison of Main Resin Series

| Product Series | Appearance | Viscosity (25℃, mPa·s) | Density (g/cm³) | Solid Content (%) | Flash Point (°C) | Shelf Life (Months) | Key Characteristics |

|---|---|---|---|---|---|---|---|

| Epoxy Resins | Clear to pale yellow liquid | 500 - 15,000 | 1.10 - 1.25 | 70 - 100 | >100 | 6 - 12 | High strength, excellent adhesion, chemical resistance |

| Polyurethane Resins | Clear to slight yellow liquid/solid | 200 - 8,000 (liquid) | 1.05 - 1.20 | 60 - 100 | >100 | 6 - 12 | Good flexibility, abrasion & low-temperature resistance |

| Unsaturated Polyester | Light yellow to amber liquid | 200 - 2,500 | 1.08 - 1.35 | 60 - 75 | 30 - 35 | 3 - 6 | Fast curing, cost-effective |

| Acrylic Resins | Water-white to light yellow liquid | 100 - 5,000 | 1.00 - 1.20 | 40 - 100 | 60 - 100 | 6 - 12 | Excellent weatherability, high clarity, UV curable |

Table 2: Key Cured Performance Properties

| Property | Epoxy Resins | Polyurethane Resins | Unsaturated Polyester | Acrylic Resins | Test Standard |

|---|---|---|---|---|---|

| Tensile Strength (MPa) | 50 - 90 | 20 - 60 | 40 - 80 | 20 - 50 | ISO 527 |

| Flexural Strength (MPa) | 80 - 150 | 30 - 80 | 60 - 120 | 30 - 70 | ISO 178 |

| Impact Strength (kJ/m²) | 10 - 25 | No break | 5 - 15 | 5 - 20 | ISO 179 |

| Heat Deflection Temp. (°C) | 80 - 200 | 60 - 120 | 60 - 120 | 60 - 100 | ISO 75 |

| Volume Resistivity (Ω·cm) | 10¹⁴ - 10¹⁶ | 10¹² - 10¹⁴ | 10¹³ - 10¹⁵ | 10¹² - 10¹⁴ | IEC 60093 |

International Compliance:

Chemical Safety: Compliant with EU REACH (SVHC <0.1%) and RoHS Directives.

Food Safety: Selected grades comply with US FDA 21 CFR 175.300 for food contact.

Flame Retardancy: Specific grades achieve UL 94 V-0 rating.

Environmental Standards: Low VOCs emissions; water-based and solvent-free options available.

Part 2: Our Core Advantages

1. R&D & Product Superiority

Customization Capability: Formulations can be tailored to your specific process and performance requirements.

Consistency Guarantee: Strict production process control ensures stable performance between batches.

Innovative Portfolio: Continuous R&D in eco-friendly (water-based, bio-based) and high-performance (high-temp, high-toughness) resins.

2. Quality & Compliance Edge

End-to-End QC: 18 key checkpoints from raw material intake to finished goods.

Comprehensive Certifications: ISO 9001, ISO 14001, UL recognition, REACH registration.

Complete Documentation: Each batch is shipped with Certificate of Analysis (CoA), Technical Data Sheet (TDS), and Material Safety Data Sheet (MSDS).

3. Supply Chain & Service Strength

Global Supply Network: Manufacturing bases in China, Southeast Asia, and Europe ensure stable supply.

Rapid Response: Initial inquiry response within 24 hours with targeted technical advice.

Localized Support: Technical service centers and warehouse logistics in key markets.

Flexible Supply Models: Support orders from samples (1kg) to full container loads.

4. Commitment to Sustainability

Eco-Friendly Series: Options include water-based, high-solid, and bio-based resins.

Green Manufacturing: 15% lower energy consumption than industry average.

Packaging Recycling Program: Available packaging take-back service to reduce footprint.

Part 3: Primary Application Areas

1. Composite Materials

Transportation: Lightweight automotive parts, high-speed train interiors, boat hulls.

Wind Energy: Structural adhesives and coatings for wind turbine blades.

Sports Equipment: Carbon fiber bicycle frames, golf clubs, skis.

2. Construction & Civil Engineering

Flooring Systems: Industrial wear-resistant, anti-static, and decorative floors.

Structural Strengthening: Fiber Reinforced Polymer (FRP) for concrete reinforcement.

Waterproofing: Roof coatings, tunnel sealing materials.

3. Electronics & Electrical

Electronic Encapsulation: Chip packaging materials, circuit board potting compounds.

Electrical Insulation: Transformer casting, motor insulation.

Conductive Bonding: LED assembly, display bonding.

4. Adhesives & Coatings

Industrial Bonding: Structural bonding of metals, plastics, glass.

Protective Coatings: Pipeline corrosion protection, tank linings, offshore platform coatings.

Specialty Coatings: High-temperature, antifouling, fire-retardant coatings.

5. Emerging Applications

3D Printing: Resins for Stereolithography (SLA/DLP) 3D printing.

New Energy: Battery encapsulation adhesives, fuel cell components.

Creative Industries: Craft casting, artifact restoration materials.

Part 4: Our Professional Packaging Solutions

Diverse Packaging Options

| Packaging Type | Size | Suitable For | Key Features | Minimum Order Quantity |

|---|---|---|---|---|

| Steel Drum | 200kg/drum | All liquid resins | Robust, leak-proof for long sea freight; Recyclable | 4 drums (800kg) |

| HDPE Plastic Pail | 25kg/pail, 50kg/pail | Non-strongly corrosive resins | Lightweight, easy handling; Transparent option for level check | 20 pails (500kg) |

| Tinplate Can | 5kg/can, 10kg/can | Samples / Small batches | Excellent seal, anti-oxidation; Ideal for air freight samples | 1 can (sample) |

| IBC Tote | 1000kg/tote | Large volume orders | High loading/unloading efficiency; ~15% lower packaging cost | 1 tote |

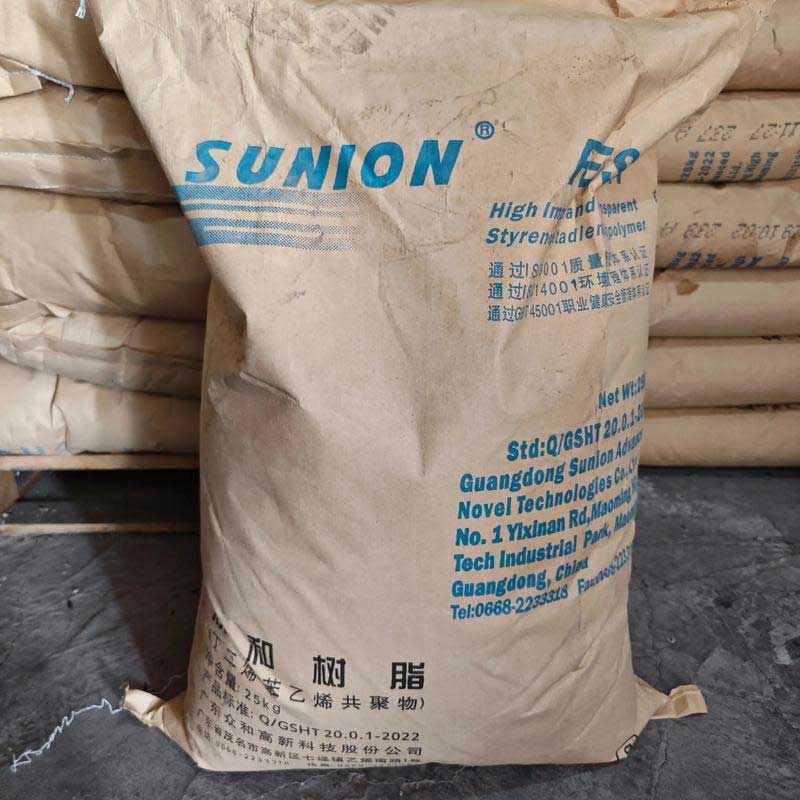

| Composite Bag | 25kg/bag | Solid / Powder resins | Moisture & oxidation barrier; Saves 80% warehouse space | 20 bags (500kg) |

International Logistics Assurance

Dangerous Goods Compliance: All packaging is UN-certified, meeting IMDG and IATA transport requirements.

Clear Labeling: Bilingual (EN/CN) labels with GHS pictograms, hazard & precautionary statements.

Complete Documentation: Full set of export documents (Invoice, Packing List, B/L, COO, MSDS).

Optimized Loading: 20-foot container fits 18-22 tons (depending on package); professional loading guidance provided.

Special Packaging Services

Mixed Container Loads (LCL): Different products in one container to optimize your inventory.

Branded Custom Packaging: Private-label packaging with your logo.

Winterized Packaging: Special insulated packaging for shipping to cold climates.

Sample Kits: Multi-product sample sets for convenient testing.