Iron Oxide Black

Economical Pigmentation: Black iron oxide provides a cost-efficient black coloring solution for ceramic applications, particularly in glaze formulations.

Thermal Stability: The pigment maintains consistent chromatic performance in high-temperature firing processes, ensuring predictable glaze coloration.

High-Purity Variants: Available in refined grades with controlled heavy metal content, meeting safety requirements for sensitive applications.

Broad Ceramic Applicability: Valued as a reliable iron source in ceramic production due to its reproducible tintorial properties and cost-efficient performance.

Black iron oxide functions as a principal iron source in ceramic production systems, particularly valued in glaze formulations for its cost-efficient pricing and inherent black pigmentation. During high-temperature firing processes, it develops stable chromatic effects in glaze matrices. The material is also produced in refined grades featuring minimized heavy metal content to meet stringent quality specifications.

Product Name: | Iron Oxide Black |

Synonyms: | c.i. 77499;C.I. Pigment Black 11;IRON OXIDE BLACK;kjasdiwals;Iron Oxide Black pharma grade;Iron Oxide Black cosmetic grade;Iron Oxide Black Food grade;Fe3O4 nanoparticle |

CAS: | 12227-89-3 |

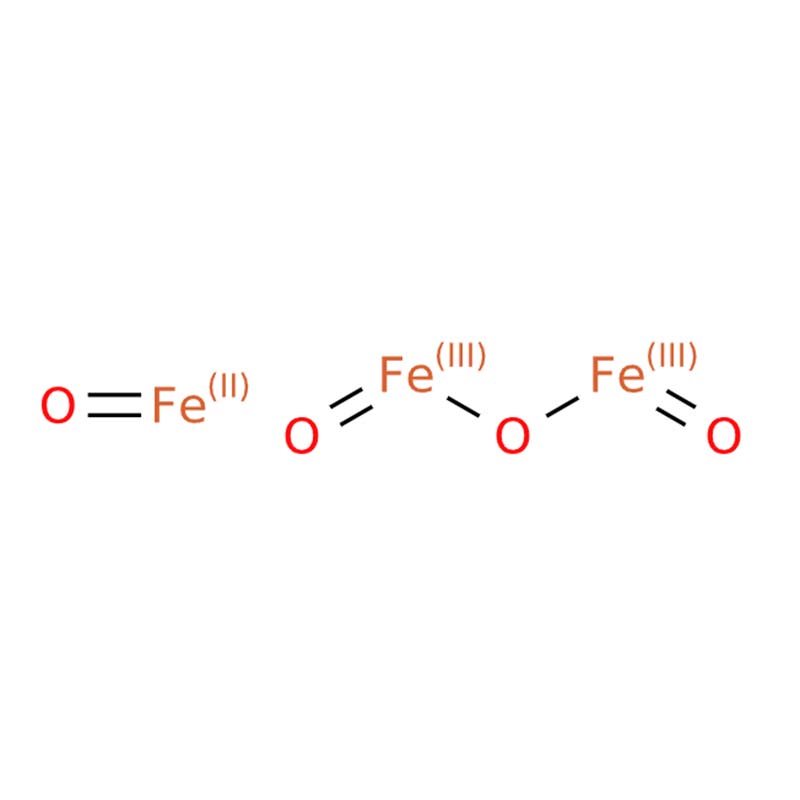

MF: | Fe3O4 |

MW: | 231.54 |

EINECS: | 235-442-5 |

Product Categories: | dyestuff |

Mol File: | Mol File |

Black iron oxide powder finds application as a coloring agent in diverse non-ceramic products. Specific iron oxide pigments are widely employed in cosmetic formulations owing to their non-toxic nature, moisture resistance, and minimal migration properties. To guarantee safety and purity, cosmetic-grade iron oxides are synthetically manufactured to eliminate impurities commonly found in naturally occurring variants. Furthermore, black iron oxide (magnetite, Fe₃O₄) is utilized for its corrosion-resistant characteristics and serves as a fundamental component in protective coatings applied to notable structures including bridges and the Eiffel Tower