Polyvinyl Chloride Resin

1. Core Features

The wide application of PVC is attributed to its unique chemical structure:

Flammability Resistance: The PVC molecule contains chlorine (accounting for approximately 57% of its weight), making it inherently flame-retardant. Once separated from the flame, it will extinguish itself. This is the key reason why it is widely used in construction and wire conduit.

Chemical Resistance: Stable against most inorganic acids, bases, and salt solutions, it is often used in chemical pipelines and containers.

Durability: Good mechanical strength and excellent wear resistance.

Electrical Insulation: It is an excellent electrical insulating material, suitable for the insulation layer and protective sheath of wires and cables.

Adjustability: By adding different types and quantities of additives (such as plasticizers, stabilizers, fillers, etc.), its physical properties can be significantly changed, enabling the production of various products ranging from as hard as steel to as soft as rubber.

2. Main drawbacks

Poor thermal stability: Pure PVC is prone to decompose into hydrogen chloride (HCl) under the action of light and heat, so heat stabilizers must be added during processing.

Poor low-temperature resistance: It becomes harder and more brittle at lower temperatures.

The toughness needs improvement: Unmodified rigid PVC has poor impact resistance and often requires the addition of impact modifiers.

Polyvinyl Chloride is usually abbreviated as PVC. It is a high-molecular polymer made by polymerizing vinyl chloride monomer (VCM).

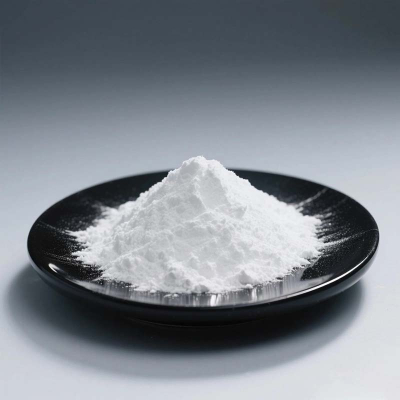

The "polyvinyl chloride resin" we usually refer to is pure PVC powder without any additives. It is the basic raw material for producing all PVC products. Pure PVC resin is white and amorphous powder. It cannot be used directly; it must be mixed with various additives and plasticized before it can be made into the final product.

Main classifications:

PVC resin is mainly divided into two categories based on the production method:

1. Suspension polymerization of polyvinyl chloride

The most common type, accounting for approximately 80-85% of the total PVC production.

The product is in the form of white granular powder.

Based on the particle morphology and pore structure, it can be further classified into "loose type" and "dense type", among which the loose type is more common. This is because it has a strong ability to absorb plasticizers and is easy to undergo plasticization processing.

Applications: Widely used in hard products (such as pipes, profiles) and soft products (such as films, cable materials).

2. Emulsion polymerization of polyvinyl chloride

The product is a fine white powder, usually ground into a paste with liquid plasticizers.

It is mainly used for manufacturing PVC paste resins.

Applications: Particularly suitable for processes such as scraping, impregnation, foaming, etc., such as artificial leather, wallpaper, gloves, toys (such as rubber dolls), automotive interiors, etc.

Production Process Overview

Raw Material Preparation: The main raw material is vinyl chloride monomer (VCM).

Polymerization Reaction: In the polymerization reactor, through the action of initiators, VCM molecules are connected to form long-chain PVC molecules. This process is usually carried out under certain temperatures and pressures.

Recovery of Unreacted Monomers: After the reaction is complete, the unreacted VCM is recovered and recycled.

Post-Treatment: The PVC slurry obtained from the polymerization process is dehydrated and dried to obtain powdered PVC resin.

Packaging: The finished products are packaged and stored.

Main application fields

The application of PVC is extremely extensive, mainly divided into hard products, soft products and paste resin products.

Polyvinyl chloride resin, as an important organic material, is widely used in the production of various industrial sectors such as industry, agriculture, medicine, food, construction, civilian use, pipes, profiles, plates, cables, plastic packaging products, various films, etc.

Category | Primary Products | Features |

Hard PVC (UPVC/RPVC) | Architecture and Building Materials: Door and window profiles, rainwater pipes, wall protection panels, floor base materials. | Without adding or adding a small amount of plasticizers, it has good rigidity and high strength. |

Soft PVC (SPVC) | Daily necessities: tablecloths, shower curtains, hoses, inflatable toys. | When a large amount of plasticizers is added, it becomes flexible, easy to bend and has a good feel. |

PVC paste resin | Coated products: artificial leather, tarpaulin, gloves, wallpaper. | At room temperature, it is in a paste-like state. It is gelified through heating to form a shape, which is suitable for complex shapes. |

Composition of Different PVC Products (Representative Formulations) | ||||

Product Type | PVC Resin | Plasticizer | Heat Stabilizer | Filler |

Rigid PVC | ~80-95% | 0 or minimal amounts | 2-4% | 5-10% |

Flexible PVC | ~50-70% | 25-40% | 2-3% | 5-15% |

Polyvinyl Chloride Resin (Product Specifications)

Contents | SG3 | SG5 | SG8 | YHXP-5 | |

Viscosity Number (ml/g) | 135-127 | 118-107 | 86-73 | 118-107 | |

K-value | 72-71 | 68-66 | 59-55 | ||

The average degree of polymerization | 1370-1251 | 1135-981 | 740-650 | ||

Number of Impurity Particles (count) | 16max | 16max | 20max | 16max | |

Volatile Matter (including water) Mass Fraction (%) | 0.30max | 0.40max | 0.40max | 0.40max | |

Apparent Density (g/ml) | 0.45min | 0.48min | 0.52min | 0.48min | |

Sieve residue(%) | Residue on Sieve (%) - 250 μm Mesh | 1.6max | 1.6max | 1.6max | 2.0max |

Residue on Sieve (%) - 63 μm Mesh | 97 min | 97 min | 97 min | 90 min | |

Fish Eye Count (per 400 cm²) | 20max | 20max | 30max | 20max | |

Plasticizer Absorption (g/100g resin) | 26 min | 19min | 12min | 20min | |

Whiteness (% after 10 min at 160°C) | 78min | 78min | 75min | 80min | |

Residual Vinyl Chloride Monomer Content (ppm) | 5max | 5max | 5max | 5max | |

Contents | YHHP-1800 | YHHP-2500 | YHHP-2700 | YHHP-3000 | |

The average degree of polymerization | 1750-1900 | 2400-2600 | 2601-2800 | 2900-3100 | |

Number of Impurity Particles (count) ≤ | 16 | 16 | 16 | 30 | |

Volatile Matter (including water) Mass Fraction / % ≤ | 0.30 | 0.30 | 0.30 | 0.40 | |

Apparent Density / (g/mL)≥ | 0.45 | 0.42 | 0.40 | 0.38 | |

Sieve residue(%) | 250 μm Mesh | 3.0 | 3.0 | 3.0 | 8.0 |

63 μm Mesh | 98 | 98 | 98 | 92 | |

Plasticizer Absorption / (g/100g resin) ≥ | 25 | 27 | 27 | 29 | |

Whiteness / (% after 10 min at 160°C) ≥ | 80 | 80 | 80 | 80 | |

Residual Vinyl Chloride Monomer Content / (μg/g)≤ | 2 | 2 | 2 | 2 | |

Fish Eye Count / (count/400cm²)≤ | 20 | 20 | 20 | 20 | |

Aqueous Extract Conductivity / [μS/(cm·g)]≤ | 5 | 5 | 5 | 5 | |