Polyethylene Terephthalate

Outstanding Stability and Clarity: Ensures excellent dimensional stability and optical transparency, making it ideal for applications such as LCD films.

Exceptional Mechanical Strength: Delivers superior resistance to fatigue, abrasion, and aging across a broad temperature range.

Superior Insulation and Chemical Resistance: Provides reliable electrical insulation and stability against most organic solvents and inorganic acids.

Energy-Efficient and Adaptable: Boasts low energy consumption and excellent processability, making it a perfect choice for packaging, films, and fibers.

Product Details

Polyethylene terephthalate (PET) resin is commonly employed as the exterior film for LCD screens. Known for its exceptional dimensional stability and high optical clarity, PET polyester film finds extensive application across numerous industries. This material preserves its superior mechanical and physical properties across a broad temperature spectrum, offering remarkable resistance to fatigue, wear, and aging. Additionally, PET provides excellent electrical insulation and maintains stability when exposed to most organic solvents and inorganic acids. Its low energy consumption and ease of processing further enhance its versatility. As a result, PET is widely adopted in the production of plastic packaging bottles, films, and synthetic fibers.

Product Parameters

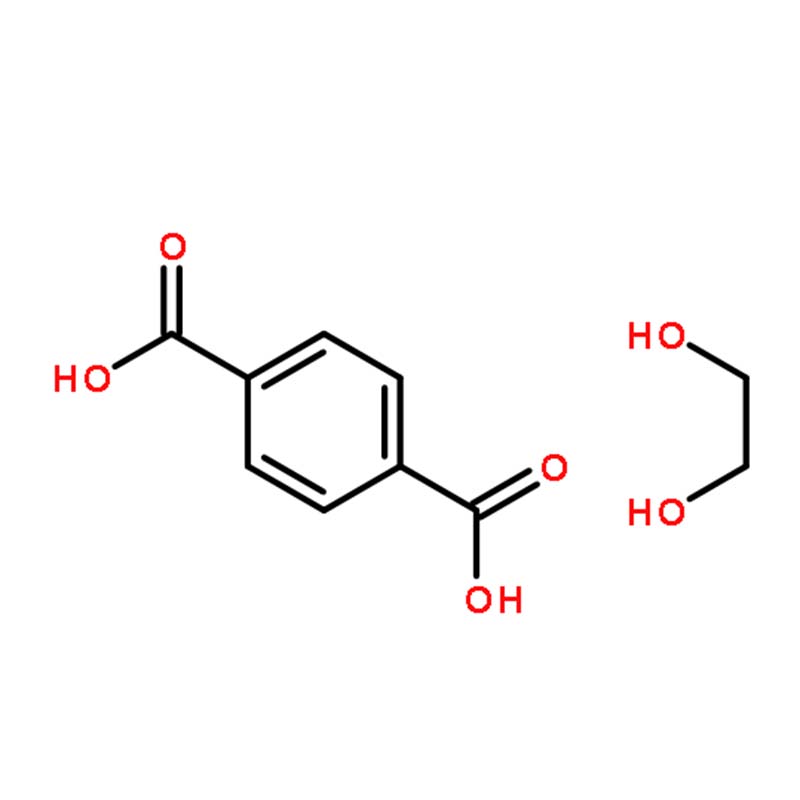

English name | Polyethylene Terephthalate |

English synonyms | 3DXNANO ESD CNT-PETG carbon nanotube reinforced polyethylene terephthalate glycol copolymer 3D pri nting filament;arnitea;arnitea-049000;arnitea200;arnitefp800;arniteg;arniteg600;Cassappret sr |

CAS number | 25038-59-9 |

Molecular formula | (C10H804)n |

Molecular weight | 228.19868 |

Melting point | 250-255°C |

Boiling point | >170°C (Press: 10 Torr) |

Density | 1.68 g/mL at 25°C |

Refractive index | 1.575 |

Storage conditions | Room Temperature |

Appearance | Granular |

Color | Black |

Odor | Odorless |

Polyethylene terephthalate resin, also known as polyester chips, serves as a primary material in three major applications: bottle-grade polymer for beverage containers (particularly carbonated drinks), polyester film for packaging, photographic films, and adhesive tapes, as well as fiber-grade polyester used in chemical fiber production.

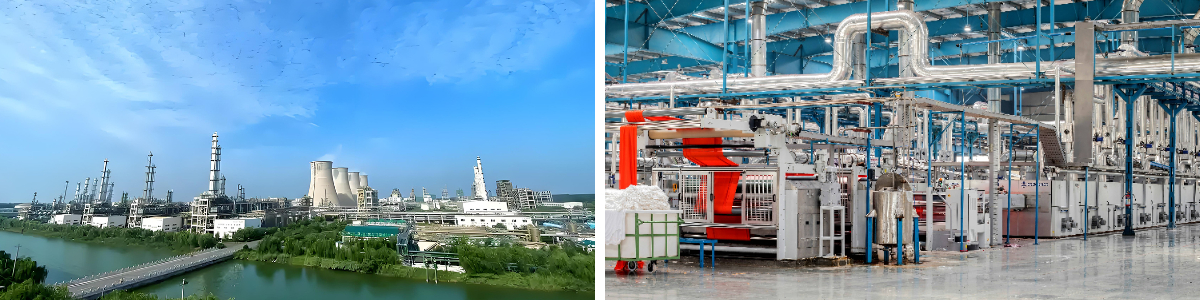

About Us

We are a professional manufacturer specializing in the research, development and production of chemical products, with an annual production capacity of over 10,000 tons. Thanks to our excellent product quality and stable supply capabilities, our annual sales volume exceeds 30,000 tons, with over 60% of the products exported to foreign countries. Our products are widely recognized and trusted by both domestic and foreign users.